Pulp and Paper

PULP AND PAPER industry uses several processes to convert wood fibre into cellulose pulp, which is then manufactured into paper, newsprint, cardboard and thousands of other products. The basic pulp process is to reduce wood to fibre by mechanical means or by heating in chemical solutions. To make paper, the fibres are mixed with water and extruded in continuous sheets, which are pressed and dried. Some BC mills produce pulp only, which is shipped to other mills at home or abroad for use in paper or chemical manufacturing. Some mills also produce newsprint, while several mills use BC pulp to manufacture writing, photocopy and other fine papers. In 2006 there were 24 pulp and paper mills operating in the province.

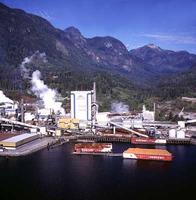

BC's first paper mill was opened by the BC Paper Manufacturing Co at PORT ALBERNI in 1894. Because it was designed to use rags as raw material it was unable to utilize local wood for pulp; it failed after 2 years. A few years later the provincial government made pulp leases on Crown timber available to encourage the development of a pulp and paper industry. Several companies were formed and obtained leases, but it was not until 1909 that mills began operating: one a pulp mill at SWANSON BAY on the north BC coast, and the second a pulp and paper mill at PORT MELLON on HOWE SOUND. The POWELL RIVER newsprint mill, the first in BC and one of the largest in the world, began production in 1912. The same year the Whalen family opened a pulp and paper mill at WOODFIBRE on Howe Sound and in 1916 they took over the Swanson Bay mill, which operated for another decade. A Whalen-owned pulp mill also began operating at PORT ALICE on the northwest coast of VANCOUVER ISLAND in 1918. In 1917 Pacific Mills opened the province's second newsprint mill at OCEAN FALLS; it operated until 1980, then closed for lack of timber. In 1912 the Sidney Roofing & Paper Co built a small paper mill on the SAANICH PENINSULA to manufacture asphalt roofing material and construction paper, and in 1923 Westminster Paper Mills (later SCOTT PAPER LTD), opened a tissue paper mill in NEW WESTMINSTER. This was the last new mill until after WWII.

During the war many chemical-based uses for cellulose were discovered; when the war ended there was an immense demand for pulp. Two new mills were built shortly after armistice, one by BLOEDEL, STEWART & WELCH at Port Alberni, and another by the H.R. MacMILLAN Export Co at Harmac, near NANAIMO. When Forest Management Licence tenures were created in 1948 (see FOREST POLICY) they were used to spur development of several pulp mills. The American Celanese Corp opened pulp mills at PRINCE RUPERT (1951) and CASTLEGAR (1960)—the Interior's first pulp mill. CROWN ZELLERBACH's Elk Falls pulp and newsprint mill at CAMPBELL RIVER opened in 1952. BC FOREST PRODUCTS started production at its CROFTON pulp mill in 1958, and in 1964 a newsprint mill was added. MacMILLAN BLOEDEL opened the Island Paper fine paper mill in VANCOUVER in 1960. The Tahsis Company opened a pulp mill at GOLD RIVER in 1967, to which a newsprint mill was added in 1990. (By 1999 both operations had shut down.) Eurocan Pulp and Paper Co opened a pulp and paper mill at KITIMAT in 1969. Throughout the late 1960s and 1970s large integrated FOREST PRODUCTS complexes were built in the Interior. These mills obtained most of their raw material in the form of waste from SAWMILLS and plywood plants. The development of a new type of high-speed saw, the Chip-n-Saw, cut small logs into lumber, with the unused portion turned into pulp chips. In 1966, 3 new mills opened in the Interior, one at KAMLOOPS and 2 at PRINCE GEORGE. Two years later Intercontinental Pulp Co opened Prince George's third pulp mill. CRESTBROOK FOREST INDUSTRIES opened a pulp mill at SKOOKUMCHUCK in the E KOOTENAY in 1969. A small groundwood mill, the first in BC using this process, was opened by Finlay Forest Products at MACKENZIE in 1971. (This mill was later sold to the Montreal company Donahue Inc). In 1972 Cariboo Pulp and Paper opened a mill at QUESNEL and BC Forest Products opened a mill at Mackenzie. WEST FRASER TIMBER opened Quesnel's second mill in 1980. In 1987 a consortium of Interior sawmills opened the Fibreco pulp mill at TAYLOR, and in 1991 Louisiana Pacific began operations at its CHETWYND pulp mill. In 2001 Norske Skog Canada Ltd (formerly FLETCHER CHALLENGE CANADA) purchased rival PACIFICA PAPERS, creating N America's third-largest paper company with paper mills at Port Alberni, Powell River, Crofton, and Elk Falls and a pulp mill at Mackenzie which it later sold to Pope & Talbot Inc. Pacifica became the Catalyst Paper Corp in 2004 and Norske Skog sold its interest in the company the following year.

As the timber supply tightened during the 1980s and 1990s, large sums were invested in rebuilding many of the established mills to make them more efficient. Others expanded their capacity, and all of them spent large amounts of money installing new equipment to reduce toxins in the effluents dumped into river and ocean waters (see ENVIRONMENTAL MOVEMENT). In 1991 Newstech Recycling opened BC's first paper recycling plant in New Westminster, producing de-inked pulp. The BC pulp and paper industry employs more than 12,000 people. In 2003 it produced 4.5 million metric tonnes of market pulp and 2.9 million tonnes of newsprint. Total value of pulp and newsprint sales was $4.5 billion. Nonetheless, by 2005 the sector's share of total BC exports had fallen to 8% from 19% just 15 years earlier. See also FOREST INDUSTRY.

by Ken Drushka